Use of Modified Asphalt with Gilsonite

The infrastructure of modern societies is heavily reliant on high-quality road construction materials, with asphalt playing an important role in ensuring long-lasting, safe, and cost-effective pavements. Over the last century, the addition of gilsonite to asphalt mixtures has emerged as a transformative technique for improving asphalt performance. Modified asphalt with gilsonite, a specialized type of asphalt, not only improves mechanical properties but also has economic and environmental benefits, making it an important consideration for engineers, municipalities, and road construction specialists around the world.

Read this article by Biskim. Learn more about modified asphalt with gilsonite.

Introduction to Modified Asphalt with Gilsonite

Gilsonite, a natural hydrocarbon resin, has been used as an asphalt additive for more than a century. Despite its long history, gilsonite’s full potential in modified asphalt has not been thoroughly evaluated in many regions, limiting widespread awareness of its benefits. Nonetheless, field trials have consistently demonstrated that using gilsonite can significantly improve pavement durability and functionality. Modified asphalt with gilsonite has increased resistance to rutting, cracking, and surface wear, resulting in longer-lasting roads and lower maintenance costs.

Gilsonite’s primary function in asphalt is to harden the binder while keeping it flexible. Gilsonite improves adhesion between asphalt and aggregates, making pavements more resistant to stresses. This modification is especially important in areas with harsh weather conditions, where traditional asphalt can fail prematurely due to cracking or deformation.

Economic Importance of High-Quality Modified Asphalt

One of the most compelling reasons to use modified asphalt with gilsonite is its economic benefits. Asphalt surface production, implementation, maintenance, and repair take up a significant portion of municipal budgets, civil engineering projects, and transportation expenditures. Conventional asphalt frequently requires maintenance or resurfacing, raising the lifecycle cost of roads.

By incorporating gilsonite into the asphalt binder, pavements can last more than two to three times as long as standard asphalt. This increase in durability results in significant cost savings for public and private infrastructure projects. Furthermore, if the additive material is inexpensive, the cost of manufacturing modified asphalt can be reduced. Gilsonite, for example, is an economically viable solution for large-scale paving projects due to its low cost and performance-enhancing properties.

Furthermore, by reducing maintenance requirements, modified asphalt with gilsonite reduces traffic disruptions, lowering indirect costs associated with roadworks such as fuel consumption, vehicle wear and tear, and lost productivity. As a result, using gilsonite-modified asphalt reduces construction costs while also increasing overall economic efficiency.

Environmental Advantages of Using Gilsonite

Environmental considerations are becoming more important in modern infrastructure development. Petroleum-based bitumen contains heavy aromatic compounds that can gradually leach into the environment via erosion or rainfall, contaminating soil and water systems. Adding gilsonite to asphalt mixtures can significantly reduce these environmental risks.

Modified asphalt containing gilsonite contributes to a more sustainable construction approach. Making asphalt that is more durable and resistant to degradation reduces the need for resurfacing projects, lowering the raw material and energy consumption associated with asphalt manufacturing. Furthermore, gilsonite-modified asphalt is generally less toxic than conventional asphalt, which reduces its impact on nearby ecosystems during its service life.

Another significant advantage of using gilsonite is that it helps to preserve natural resources. Asphalt is made from nonrenewable petroleum resources, so conserving them is critical for long-term sustainability. Gilsonite helps reduce the overall consumption of raw bitumen by improving asphalt pavement durability and longevity, which aligns with global conservation policies and promotes responsible resource management.

Technical Aspects and Performance Benefits

The performance characteristics of modified asphalt with gilsonite have been well documented in laboratory studies. Asphalt mixtures containing 5 to 15 percent gilsonite have higher hardness, stiffness, and overall strength than unmodified asphalt. For example, tests have shown that asphalt hardness with 10% gilsonite reaches 1357 kg, compared to 1097 kg for conventional asphalt. This significant increase in rigidity results in longer-lasting pavements that can withstand high traffic loads and environmental stresses.

Another significant advantage is improved thermal stability. Gilsonite-modified asphalt has higher resistance to thermal cracking, especially at low temperatures.

This property is critical in regions with harsh winters, where asphalt contraction and cracking are common issues. Furthermore, gilsonite increases the viscosity of the binder, improving its adhesion to aggregates and decreasing the likelihood of water infiltration, which is a common cause of potholes and surface deterioration.

Benefits of Gilsonite in Asphalt

- Increased durability: When compared to conventional asphalt, gilsonite-modified pavements last significantly longer.

- Improved thermal resistance: Increased resistance to both high-temperature rutting and low-temperature cracking results in better performance across climates.

- Longer-lasting asphalt means fewer repairs and resurfacing, which saves money on maintenance.

- Environmental safety: Reduced leaching of harmful aromatic compounds protects soil and water systems.

- Cost-effectiveness: Because of its high performance and low production costs, gilsonite is an ideal additive for large-scale projects.

These benefits explain why modified asphalt with gilsonite has become the standard in modern pavement engineering.

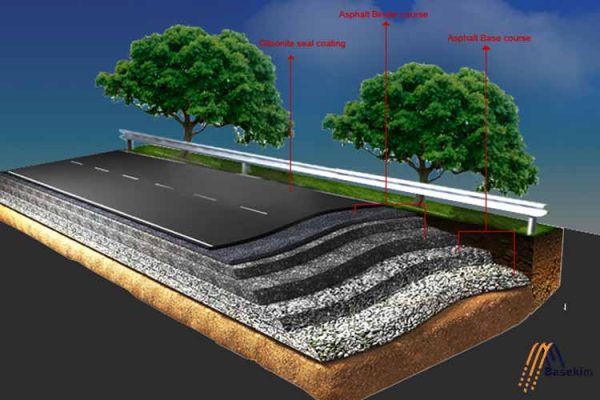

Practical Applications and Use in Road Construction

Modified asphalt containing gilsonite is commonly used in highway and urban road construction, airport runways, and industrial pavements. Its ability to improve mechanical properties and durability makes it appropriate for both high-traffic and low-traffic environments. Highways and airports benefit the most from gilsonite-modified asphalt because they face constant heavy loads and extreme weather conditions.

To ensure uniform distribution, the gilsonite must be carefully blended into the asphalt. Typically, 5 to 15% gilsonite is incorporated into the binder by weight. Proper mixing allows the modified asphalt to achieve optimal hardness, viscosity, and adhesion. One key consideration for engineers is how to melt oxidized bitumen effectively, as maintaining the right temperature is essential to create a homogeneous blend and fully realize the benefits of gilsonite in the final pavement.

Asphalt Additives Gilsonite

In addition to its primary function as a modifier, gilsonite can be combined with other asphalt additives to improve pavement performance. For example, combining Gilsonite with polymer modifiers or crumb rubber can result in a highly resilient asphalt suitable for specialized applications such as heavy industrial zones or regions with extreme weather conditions. Gilsonite’s synergistic properties make it a versatile and valuable component in modern asphalt technology.

Long-Term Benefits and Maintenance Considerations

Investing in modified asphalt with gilsonite improves initial pavement quality while also providing long-term benefits in terms of maintenance and lifecycle costs. Roads built with gilsonite-modified asphalt require less frequent resurfacing, lowering labor, material, and machinery costs. This also reduces traffic disruptions, which improves overall public convenience and safety.

Gilsonite’s contribution to improved skid resistance and surface texture increases road safety. Reduced cracking and rutting pose fewer hazards to vehicles, lowering the likelihood of accidents and associated economic losses. The combination of economic, environmental, and safety benefits highlights the strategic value of using modified asphalt with gilsonite in infrastructure projects.

BASEKIME: Delivering Quality Bitumen Worldwide

BASEKIME is a dependable partner for businesses and professionals looking for high-quality bitumen and asphalt solutions. All grades of bitumen are available in a variety of packaging options in accordance with EN and ASTM standards, with pre-verification of conformity provided by SGS, BV, Intertek, and Cotecna.