Comparison of Bio-Bitumen vs. Petroleum Bitumen in Modern Roads

Comparison of Bio-Bitumen vs. Petroleum Bitumen in Modern Roads Every nation’s economy depends on its road infrastructure, and the selection

All grade of Bitumen in various types of packing as per EN and ASTM standard along with pre verification of conformity by SGS, BV, Intertek and Cotecna.

Penetration Grade Bitumen: includes 10/20, 15/25, 20/30, 30/40, 35/50, 40/50, 50/70, 60/70, 65/105, 70/100, 80/100, 85/100, 100/120, and 200/300. These are used based on temperature zones and traffic load.

Viscosity Grade Bitumen (VG):like VG-5, VG-10, VG-20, VG-30, VG-40, and VG-50 are commonly used in hot climates and heavy-duty roads.

Performance Grade Bitumen (PG):includes PG 46-34, PG 52-28, PG 58-22, PG 64-10, PG 64-22, PG 70-22, PG 76-10, PG 76-22, PG 82-22, and PG 88-28, offering excellent performance under extreme weather and load stress.

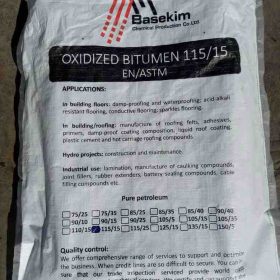

Oxidized Bitumen (Blown Bitumen): grades include 75/25, 80/30, 85/25, 85/40, 90/10, 95/25, 95/35, 100/15, 105/35, 110/30, and 115/15, ideal for roofing, industrial floors, mastics, and pipe coating.

Cutback Bitumen: includes RC-30, RC-70, RC-250, RC-800, RC-3000; MC-30, MC-70, MC-250, MC-800, MC-3000; SC-70, SC-250, SC-800, SC-3000, used for primer and cold mix applications.

Bitumen Emulsion: grades such as CRS-1, CRS-2, CMS-2, CMS-2H, CSS-1, CSS-1H, SS-1, SS-1H, RS-1, RS-2 are used in tack coats, fog seals, and slurry seals.

Polymer Modified Bitumen (PMB): includes PMB 40, PMB 70, PMB 120, PMB 130/40, and PMB 140/80, ideal for high-stress, high-traffic areas.

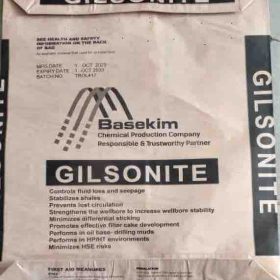

Natural Bitumen called Gilsonite: which is using for oil well drilling, waterproofing and pipe coating along with foundry and Ink also chemical industries.

Bitumen membranes: are advanced waterproofing solutions made from modified bitumen compounds reinforced with polyester, fiberglass, or composite carriers include APP Bitumen Membrane, SBS Bitumen Membrane, Self-Adhesive Bitumen Membrane along with Granule, Aluminimum and sand plus PE coating.

View Our Articles

Comparison of Bio-Bitumen vs. Petroleum Bitumen in Modern Roads Every nation’s economy depends on its road infrastructure, and the selection

Smart Asphalt: Integrating Sensors for Road Performance Monitoring Smart asphalt has evolved from experimental research to real-world implementation, reshaping our

Cold Mix Bitumen: Advantages, Applications, and Limitations Maintaining smooth and durable roads is an ongoing challenge, especially when weather and

Packing

View Our Latest News

Bitumen Prices Surge Amid Iran-Israel Conflict – June 2025 The ongoing military conflict between Iran and Israel has caused serious

Background of Putin’s Statement On Thursday, Russian President Vladimir Putin delivered a pointed message to the United States and Western

A maintenance shutdown at Repsol’s 220,000 barrels per day (b/d) Bilbao refinery will significantly impact the company’s bitumen production, with