Table of Contents

Bitumen 60/70

As a leading supplier of Bitumen 60/70 based in Dubai, we cater to the global market with our high-quality bitumen products. Exporting from UAE ports, we provide bitumen in jumbo bags and drums, especially for bulk shipments. Our bitumen is recognized for its superior quality in the Middle East. In addition, we offer Gilsonite, a natural bitumen variant, which enhances the performance of asphalt mixtures in road construction. Partnering with public government refineries ensures we deliver consistent quality and quantity, offering long-term support to our clients throughout their road projects.

Download the Specification of Bitumen 60/70

MSDS of Bitumen 60/70

Why specification of Bitumen 60/70 is important?

Bitumen 60/70 one of the most commonly used grades of bitumen in road construction and industrial applications. Specification is important since Its widespread use stems from its optimal balance between hardness and flexibility, making it a favorite choice for asphalt pavements that must endure heavy traffic and diverse climatic conditions. This guide will take you deep into the physical and chemical attributes of Bitumen 60/70, its production methods, testing procedures, and much more.

Physical Properties of Bitumen 60/70

Penetration Value

Softening Point

Ductility

For Bitumen 60/70, ductility should exceed 100 cm. The bitumen can stretch over a meter without snapping, an essential property for handling temperature-induced expansion and contraction. High ductility ensures the bitumen can absorb stress without failure

Understanding Bitumen Grade 60/70

Bitumen 60/70 refers to its penetration value, which measures the hardness or softness of the bitumen. This is determined by how deep a standard needle penetrates the bitumen sample under specific conditions, measured in tenths of a millimeter. Penetration Grade 60/70 means the penetration value ranges between 60 and 70 units, making it a medium-hard bitumen. This balance makes it ideal for road construction and various industrial applications.

Why Choose the Basekim as your source for Bitumen 60/70?

We are in UAE and Turkey strategic location, advanced infrastructure, and adherence to international quality standards make it a prime source for bitumen supply. With access to high-grade crude oil, the country ensures consistent production of superior bitumen products.

- High-Quality Standards: UAE suppliers adhere to ISO, EN and ASTM standards.

- Global Accessibility: Proximity to international shipping routes enables timely deliveries worldwide.

- Advanced Production Facilities: Cutting-edge technology ensures consistent quality.

Drum Packaging

- Specifications: Durable steel drums, often coated internally for added protection.

- Advantages: Prevents contamination, easy handling.

- Use Case: Ideal for small to medium-scale projects.

Jumbo Bags

- Specifications: Polypropylene jumbo bags with inner polyethylene lining.

- Advantages: Cost-effective and suitable for medium-scale transport.

- Use Case: Preferred for construction sites requiring bulk material in manageable quantities.

Bulk Supply

- Specifications: Delivered in tankers with heating systems to maintain viscosity.

- Advantages: Economical for large-scale operations.

- Use Case: Best suited for high-volume industrial projects.

Our markets:

- Asia: Growing demand in India, China, Vietnam, Indonesia, UAE, Myanmar, Malaysia , Thailand, and Southeast Asia for infrastructure projects.

- Africa: High demand in developing nations for road construction in Kenya, Ethiopia, Tanzania, South Africa, Congo, Gabon, Ghana, Djibouti, Egypt, Algeria and other East and West African countries.

- Europe: Sophisticated requirements for sustainable and high-quality materials in Romania, Bulgaria, Ukraine, Greece and Italy.

- North America: Focus on asphalt production for highways and roofing in Brazil, Paraguay, Uruguay, Peru, Colombia, Chile , Bolivia, Argentina and Guyana and other.

Chemical Composition of Bitumen 60/70

Hydrocarbon Structure

So far Bitumen 60/70 is composed predominantly of complex hydrocarbons. Around 95% of its content is hydrocarbons, while the remaining 5% consists of sulfur, oxygen, nitrogen, and trace metals. These hydrocarbons are classified into four main groups:

Asphaltenes: Provide rigidity and stiffness.

Resins: Offer bonding characteristics.

Aromatics: Contribute to fluidity.

Saturates: Add to the flexibility.

The balance among these four determines how the bitumen behaves under stress, heat, and pressure. Bitumen 60/70 offers a well-balanced mix, making it durable and flexible.

The carbon-to-hydrogen ratio and the molecular weight of the compounds within bitumen can significantly influence its performance. Engineers and chemists study these components in labs to ensure the batch meets regulatory and project-specific standards.

Additives and Impurities

While bitumen is primarily hydrocarbon, certain additives are introduced to improve its performance. These include:

Anti-stripping agents: To enhance adhesion with aggregates.

Polymers: For increased elasticity and temperature resistance.

Fibers: To improve strength and durability.

However, bitumen can also contain impurities like water, dust, or other residues from the refining process. These impurities can negatively impact performance, which is why stringent quality control tests are a must.

Comparing Bitumen 60/70 and 80/100

Both grades fall under the penetration category, but Bitumen 80/100 is softer than 60/70, with a lower softening point. By heating and vaporizing, Bitumen 80/100 can transform into 60/70.

Refining Crude Oil

Lastly Bitumen 60/70 is primarily obtained through the distillation of crude oil in refineries. The process begins with the heating of crude oil to high temperatures in a distillation column, where lighter hydrocarbons such as gasoline, diesel, and kerosene are separated and collected from the top. What remains at the bottom is a heavy residue known as vacuum residue.

This vacuum residue is further processed to extract bitumen. The separation occurs in two main stages:

Atmospheric Distillation: This removes the lightest fractions like gas and naphtha.

Vacuum Distillation: Operated under reduced pressure, this extracts heavier fractions, leaving behind bitumen.

Bitumen derived through this method is called straight-run bitumen. It typically has excellent waterproofing and adhesive properties, and is often used directly or modified depending on its final application.

The key here is that no chemical additives are required in this stage; the bitumen’s composition is dictated by the crude oil source and refining technique. The refining process ensures the bitumen reaches the proper viscosity and penetration index necessary for its classification as 60/70 grade.

Air Blowing Method

In some cases, especially when bitumen needs to be harder or more heat-resistant, it undergoes air blowing. This process involves passing air through the vacuum residue at elevated temperatures (around 230°C–260°C). The air reacts with the hydrocarbons, causing oxidation and polymerization. This alters the bitumen’s structure, increasing its softening point and reducing its penetration value.

The air-blown bitumen often has enhanced performance characteristics such as increased resistance to water damage and better aging properties. However, care must be taken to control the process tightly, as excessive air-blowing can lead to brittleness.

For Bitumen 60/70, air blowing is only applied when the original distillation product doesn’t meet specification. Most refineries aim to produce 60/70 grade bitumen through precise control of distillation conditions without the need for further modification.

Quality of Bitumen 60/70

We provide quality certificates with every delivery. There are four types of hot asphalt 60/70 in the market, each produced using different methods:

- Continuous Production: Produces bitumen with high molecular boundaries, ductility, and viscosity.

- Batch Production: Creates up to 100 tons per batch. This method can burn the bitumen, often failing the TFOT test.

- Blending Facility: Mixes soft and hard grades to achieve the desired 60/70 bitumen. This process avoids oxygen injection and heating, resulting in higher wax content and lower viscosity.

- Iraqi Bitumen: Made via vacuum resin, this high-viscosity product lacks movement during application. Hydrocarbons are removed through direct heating, often burning the bitumen, resulting in a positive spot test, which ideally should be negative.

Uses of Bitumen

The Bitumen is primarily used in road construction and the production of various other bitumen products, including:

- PMB (Polymer Modified Bitumen)

- Bitumen Emulsion (Water-based Bitumen)

- Liquid Bitumen (Solvent-based Bitumen)

- Bitumen Primer and Paints, Coats

- Bitumen Mastic

- Bitumen Membrane Roof Roll Sheets

Factors Influencing Bitumen 60/70 Pricing

The pricing of bitumen grades typically aligns and is influenced by three main factors:

- Fuel Oil Prices: Correlated with crude oil prices.

- Exchange Rates: Export cost calculations are affected by exchange rates; a stronger USD tends to lower prices.

- Market Demand: Driven mainly by road construction, prices fluctuate with seasonal demand, peaking in dry months like October and November.

Asphalt 60/70 Pricing in India

As a major consumer due to its extensive road network, India’s bitumen prices are influenced by domestic demand, import duties, and transportation costs. Recent trends show stable prices, but these can change based on the factors mentioned above. Contractors and suppliers closely monitor these trends to optimize costs.

Pricing Per Barrel

Bitumen costs are often discussed in terms of price per ton or per barrel. The cost of one barrel of bitumen is crucial for budgeting large-scale projects and is influenced by global oil prices, exchange rates, and local market conditions.

How to Order Bitumen

To provide a quick and accurate quote, we need details on the order quantity, grade, desired packaging, and destination. For urgent inquiries, contacting us via WhatsApp ensures a prompt response.

Quality Assurance and Certifications

We hold ISO 9001 and ISO 17025 certifications, exporting bitumen that meets ASTM/EN global standards. Typically, we conduct SGS inspections before shipment and report to clients for orders of at least 500 tons. For those who opt out of inspection costs, we provide our lab’s test report. We also collaborate with BV, Intertek, and other recognized inspection entities.

Export Volume and Packaging

Our export capacity for bitumen 60/70 is 70%, compared to 30% for 80/100. Packaging options include drums, jumbo bags, IBC tanks, flexi tanks, tankers, and vessels.

Understanding Embossed Drums

Bitumen packed within the refinery, bearing specific signage, is referred to as embossed. Prominent examples include Jey embossed, Shell embossed, and Pasargad embossed cargo.

Payment Terms

We accept LC for shipments from Turkey, with 10% deposit and balance against clearance document copies, or 30% advance and balance against BL copies. Cash payments in AED and USD are also accepted in Dubai and Turkey.

Delivery Timeline

Delivery is prompt, typically within 10 days post order confirmation, regardless of order size.

Minimum Order Quantity

The minimum order for both 60/70 and 80/100 grades starts at 20 tons for initial business, with subsequent minimums set at 100 tons after product testing.

Port of Delivery

Our bitumen is shipped from Dubai’s Jebel Ali and Turkey’s Mersin ports to markets worldwide.

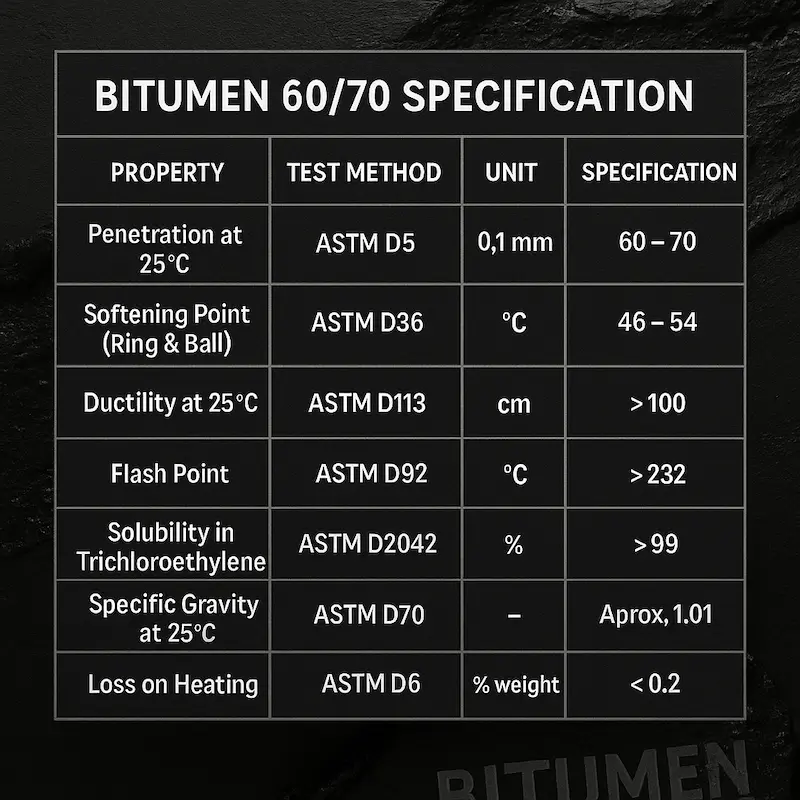

Technical Specifications of Bitumen 60/70

ASTM Standards

ASTM (American Society for Testing and Materials) is a globally recognized authority in setting technical standards for materials, including bitumen. For Bitumen 60/70, ASTM D946 and D5 are the key standards.

Here are the main technical specifications as per ASTM:

| Property | Test Method | Unit | Specification |

|---|---|---|---|

| Penetration at 25°C | ASTM D5 | 0.1 mm | 60 – 70 |

| Softening Point (Ring & Ball) | ASTM D36 | °C | 46 – 54 |

| Ductility at 25°C | ASTM D113 | cm | >100 |

| Flash Point | ASTM D92 | °C | >232 |

| Solubility in Trichloroethylene | ASTM D2042 | % | >99 |

| Specific Gravity at 25°C | ASTM D70 | – | Approx. 1.01 |

| Loss on Heating | ASTM D6 | % weight loss | <0.2 |

Analysis and data sheet of bitumen 60/70

Bitumen 60/70 | Specification | Test method |

Specific gravity @ 25/25 cg | 1.01/1.06 | D-70 |

Penetration @ 25 c | 70/60 | D-5 |

Softening point c | 48/52 | D-36 |

Ductility @25 c | 100 min | D-113 |

Loss on heating(wt) % | 0.2 Max | D-6 |

Drop in penetration after heating % | 20 Max | D-6 D–5 |

Flash point c | 250 min | D-92 |

Solubility is CS2(wt) % | 99.5 Max | D-4 |

Spot test | negative | A.A.S.H.O.T102 |

FAQs:

1.What is the difference between Bitumen 60/70 and Bitumen 80/100?

Bitumen 60/70 is harder than Bitumen 80/100, with a penetration range of 60-70 deci-millimeters compared to 80-100 for the latter. This makes Bitumen 60/70 ideal for regions with moderate to high temperatures, while Bitumen 80/100 is better suited for colder climates.

2.How is Bitumen 60/70 produced?

Bitumen 60/70 is primarily produced through the distillation of crude oil in refineries. The crude oil is heated, and lighter hydrocarbons are separated from the heavier vacuum residue. This residue is processed to extract the bitumen. Sometimes, air-blowing is applied to further modify its properties for increased heat resistance.

3.What is the price of Bitumen 60/70?

The price of Bitumen 60/70 varies depending on factors like crude oil costs, transportation, and market demand. It’s best to check with suppliers for the current rate